Steel Fabrication Near Me Can Be Fun For Everyone

Wiki Article

Some Ideas on Steel Fabrication Process You Need To Know

Table of ContentsThe Of Steel Fabrication IndustryThe Best Strategy To Use For Steel Fabrication IndustryThe smart Trick of Steel Fabrication Meaning That Nobody is DiscussingSteel Fabrication Fundamentals ExplainedThe smart Trick of Steel Fabrication That Nobody is Talking About

Machining, Machining is additionally a fairly easy procedure in principle, as well as yet there is a variation that can be located in it. By its nature, it is a procedure of removing excess product from raw metal items in some means. Three of the more popular procedures of machining are called milling, turning, and also boring.This process can be done both with the aid of a certain CNC milling maker as well as manually, and also milling, as a whole, is regularly an additional process than not. Some variations of milling can be simple milling, climb milling, form milling, angular milling, and so on. Transforming is another variant of machining that uses a particularly designed machine lathe to develop a cylindrical-shaped piece by using a reducing tool to get rid of parts of a raw metal item that turns in one location.

Drilling is the easiest one out of the 3, and also it's simply as the name recommends it's the combination of a drill and a rotary reducing tool made use of to reduce holes in the raw steel item. steel fabrication industry. Shearing, Shearing is practically a variant of cutting, yet it's divided into a various group due to its unusual strategy to the procedure.

Not known Facts About Steel Fabrication Process

The cut is begun by using stress to the steel piece with the upper component of a maker (formed like a blade), which develops a crack. By using continuously pressure to the fractured metal a cut is accomplished, and the sheared edges can be burred afterward (burred as if the procedure of cleansing up the sides of the material pieces after the shearing).It is rather a widely known technique, mainly since of its adaptability it can integrate rather much any metal components. There are four sorts of welding that are the most preferred: FCAW, MIG/GMAW, SMAW, and also TIG.FCAW or Change Cored Arc Welding utilizes a wire electrode with a core that generates shielding gas, which gets rid of the need for a secondary gas resource.

It utilizes an external gas supply in mix with a solid wire electrode to avoid the steel item from interacting with numerous environmental factors, making the procedure faster as well as much more regular. SMAW or Secured Metal Arc Welding is one of the most standard variation of a welding device, it's an electrode stick that creates an electric arc when exposuring to metal, and the high temperature level of the arc's effect is what welds the steel assemble.

What Does Steel Fabrication Apprenticeship Mean?

It utilizes a tungsten electrode rod that produces short arcs, even more ideal for hefty construction - fabrication steel chart. It's one of the much more hard variations of welding and needs a highly-skilled specialist to run it properly, however it likewise helps most of metal-based items and also comes in useful even for the most intricate jobs.This post is an effort to incorporate several of the additional resources extra fundamental information on the subject in one area, from the interpretation of steel manufacture to a myriad of processes that it can take the type of.

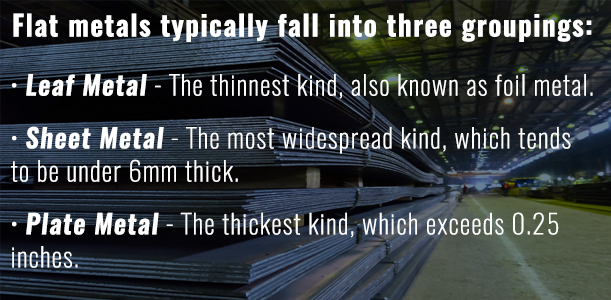

Sheet metal can be defined as any kind of steel that is developed right into slim malleable sheets. The sheets range in material from brass to titanium and come in a wide variety of predefined thicknesses, described as a gauge. Normally, a lot of sheets are less than inch thick but can vary in density from portions of a millimeter to a steel fabrication work number of inches thick.

Getting My Steel Fabrication Near Me To Work

Historically, it was used in roof shingles roof, yet as production techniques improved, sheet metal quickly used an inexpensive as well as sturdy product that might be used practically all over. It ended up being so preferred that suppliers saw a boom till The second world war when steel products became so scarce that the sector started to collapse.

Additionally, it is much faster to scale mass production due to the adaptability of construction choices. Because it is slim and has a light-weight type variable, any kind of extra stock needed for manufacturing can be stored and transported conveniently. There are lots of methods to produce sheet metal relying on the application.

Flexing, Sheet steel is placed within a bending equipment and also curved to the desired form. Stamping, A sheet metal blank is positioned right into a stamping press where it is created into the desired shape using a tool and die.

Not known Details About Steel Fabrication

This process employs using a high-powered laser to reduce materials to the desired sizes and shape. Compared to other reducing procedures, it supplies greater cutting precision and precision, particularly for facility as well as elaborate component layouts. Machining Machining is a subtractive procedure, indicating it creates parts and also items by removing material from the work surface.

Report this wiki page